Key Features

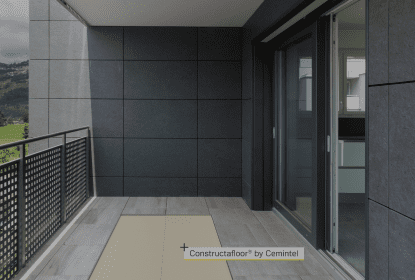

Barestone Original Cladding combines the natural beauty of concrete with the durability of fibre cement, making it perfect for modern and industrial designs. Barestone Original Cladding has a blend of warm greys and light greys. The dark valleys of the modern express joints juxtapose these light colours. This helps the geometric shapes created by the joints dominate the aesthetic.

This versatile cladding enhances both facades and interior feature walls, with the express joints providing clean lines and dynamic patterns. Panels can be oriented vertically or horizontally and arranged in various layouts like Linear, Grid, or Random.

Barestone’s warm tones pair effortlessly with other materials, especially timber accents like Territory Woodlands Teak. Available in three products—two exterior with Ceminseal and one interior with stain resistance—each panel is unique, offering natural variation in colour and pattern that adds character.

Barestone™ Applications

-

Apartment Facades

-

Ceilings

-

Commercial Facades

-

Eaves

-

External Cladding

-

Feature Walls

-

Internal Linings

-

Soffits

Explore Barestone™ Original Cladding

Barestone™ Original

The original natural concrete look. It enhances design with its smooth, light concrete appearance.

Disclaimer: Product images and samples may vary from actual product regarding colour and surface finish due to the manufacturing process and raw materials used.

Technical Information

Barestone Original Cladding Installation

Barestone™ panels are installed as a Pressure Equalised Ventilated Cavity System using the NV9 Omega top hat fixing method. This system is suitable for both residential and commercial buildings, providing durability, weather resistance, and a clean expressed-joint aesthetic.

Key Installation Elements:

- Top Hats & Centre Trims: Aluminium NV9 Omega top hats and trims support panels at vertical joints, with gasket tape applied to improve moisture management.

- Panel Fixing: Panels are pre-drilled and fixed to the top hats using Barestone™ rivets. The rivet’s rubber sleeve allows slight movement, reducing stress on the panel.

- Backing Strips: Horizontal joints incorporate backing strips to deflect water and maintain the expressed joint appearance.

- Wall Wrap & Air Barrier: A drained cavity system is used, with building wrap or rigid air barrier installed behind panels to manage condensation and incidental moisture.

- Penetrations: Cut oversize (8–10mm clearance) and fully seal with approved sealant to maintain weather performance.

- Pre-Installation Checklist: Ensure framing is plumb, bracing is in place, ground clearance is adequate, and flashings/air barriers are correctly installed before fixing panels.

Barestone Original Product Specifications

| Product Code | Description | Width (mm) | Length (mm) | Thickness (mm) | Surface Texture | Finish | Groove Spacing (mm) | Effective Cover Per Unit (m2) | Effective Width (mm) | Mass (kg/m2) | Weight Per Unit | Product Warranty (Years) | BAL |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 99486 | Barestone Original External | 1200 | 3000 | 9 | Smooth | Prefinished | n/a | 3.6 | 1200 | 17.8 | 64.08 | 10 | BAL-40 |

Technical Resources

Inspire

Latest topics, projects and people that help shape architecture, design, building and construction.

Explore our range

Find a Supplier

Order your Cemintel products through our network of suppliers, who are ready to help you get your project up and running.

Request a Sales Consult

Our dedicated sales consultants are here to help with your specifying needs. Whether you’re an architect, designer or builder, we can help you find the right prefinished product for your project.